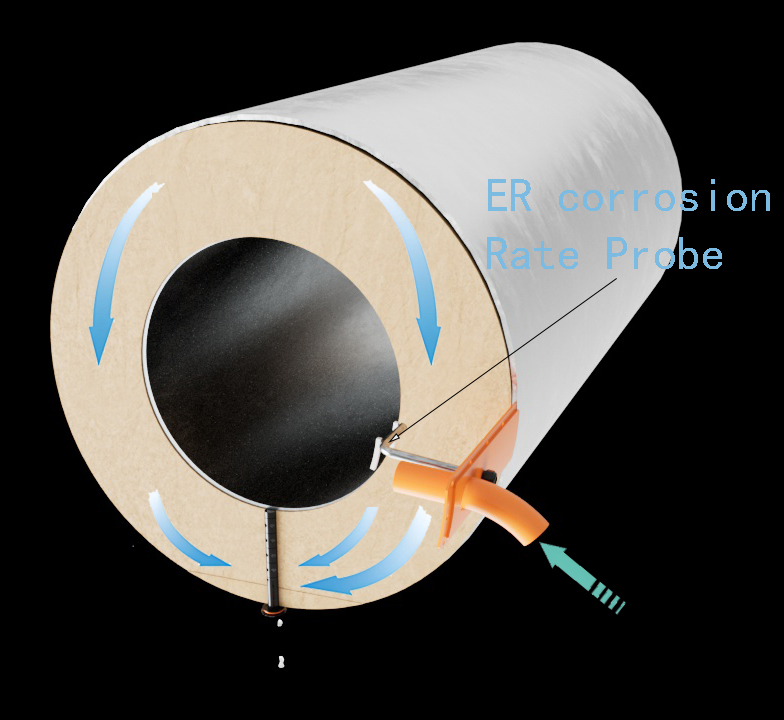

a process that combines in-line corrosion detection (using an ER corrosion rate probe), vessel inspection plugs, and a method of blowing and drying out water under insulation (WUI) through the use of a Water Under Insulation (WUI) plug equipped with a one-way valve. This setup seems to be part of a maintenance and corrosion prevention strategy in industrial vessels or piping systems, where moisture under insulation is a problem.

Let me break down this approach step by step:

1. ER Corrosion Rate Probe (In-Line Corrosion Detection)

The Electrochemical Resistance (ER) corrosion rate probe is used to continuously monitor the corrosion rate within the system. These probes are typically inserted into the system (vessel, pipeline, or tank) at specific points to measure the rate at which corrosion is occurring.

- Function in this system: The ER probe would be placed inside the vessel or pipeline to detect corrosion caused by internal moisture, acidic or corrosive materials, or other environmental factors. The corrosion data from the ER probe can then be used to trigger maintenance or corrective actions before the corrosion leads to significant damage or failure.

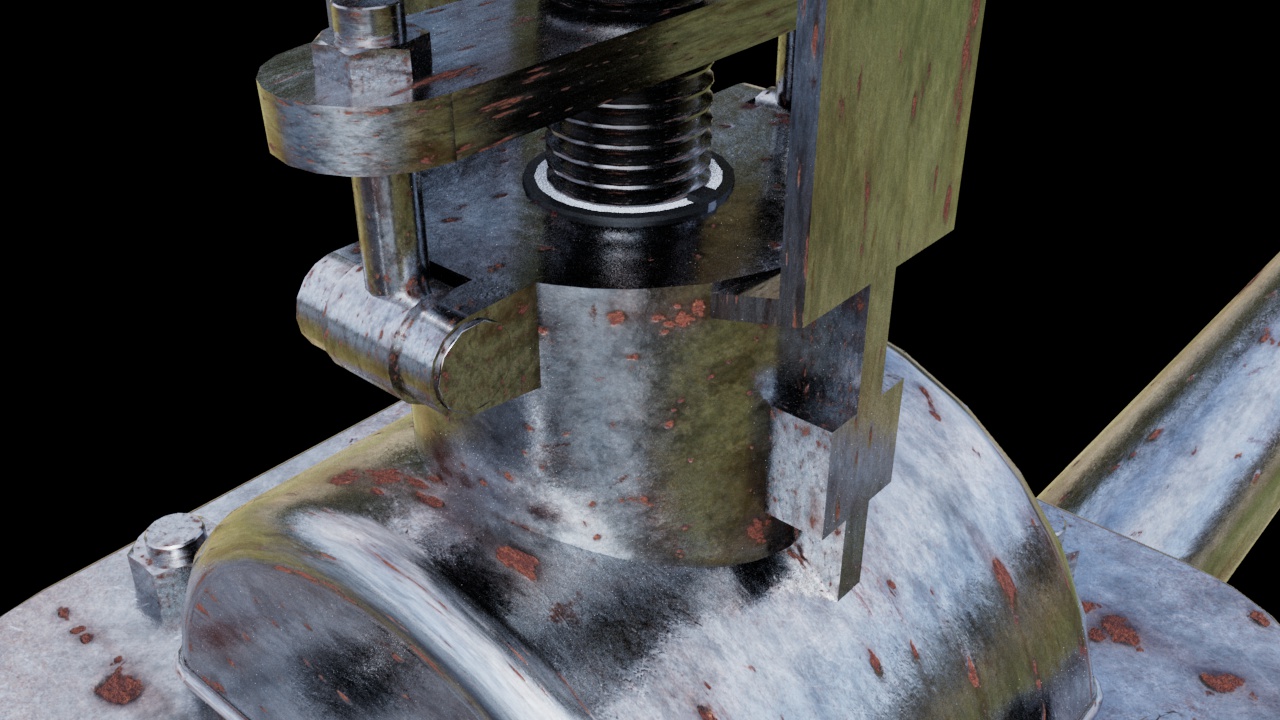

2. Vessel Inspection Plug (Inspection and Monitoring Access)

The vessel inspection plug serves as an access point to the vessel for various monitoring devices, including the ER corrosion probe.

- Function in this system: The inspection plug could allow operators to insert or remove the corrosion monitoring probe. It's typically used to ensure that the internal condition of the vessel (e.g., for corrosion or scaling) can be checked periodically without opening up the entire vessel. It also serves as an inspection point to gather physical data from the vessel's internal surfaces.

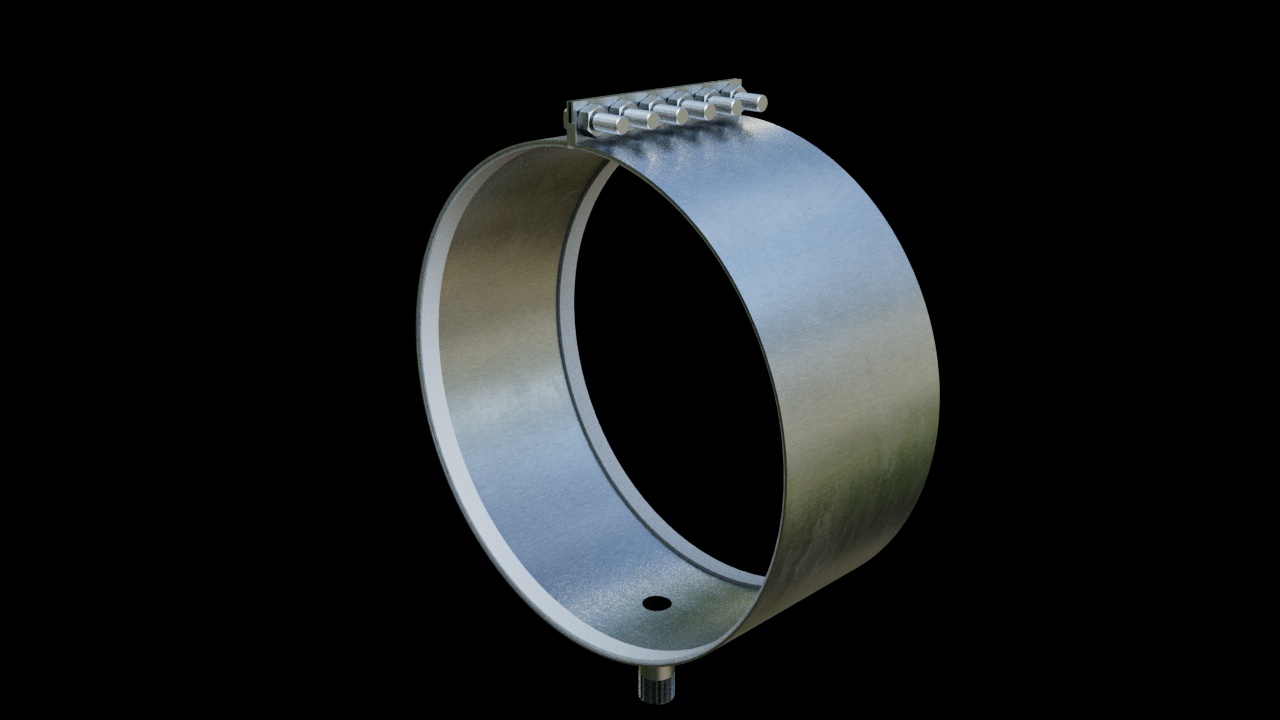

3. Water Under Insulation (WUI) Plug with One-Way Valve

Water under insulation (WUI) is a common issue in industrial systems, especially where pipes or vessels are insulated. Moisture can accumulate under the insulation, leading to accelerated corrosion and eventually failure of the system if not addressed. The WUI plug is a device installed in the insulation to manage and mitigate this issue.

-

How it works:

- The WUI plug is installed in the insulation at a critical point where water might accumulate or drain.

- The one-way valve ensures that any moisture that is trapped under the insulation can be drained out but prevents backflow of any contaminants or moisture from the environment into the system.

-

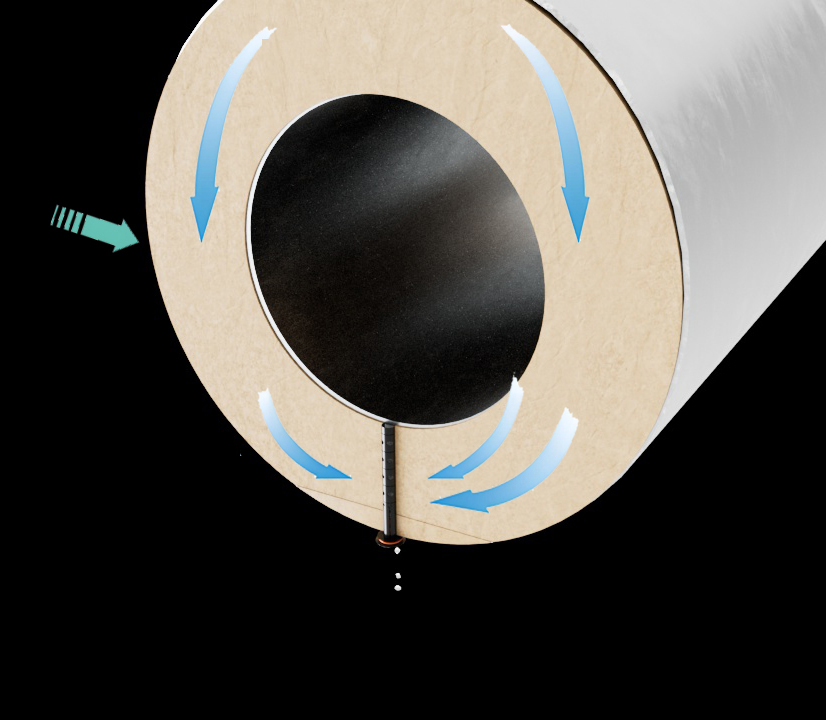

Blow and Dry Action:

- Blow: Air or nitrogen can be blown into the vessel or piping system through the inspection plug or WUI plug. The goal is to force out any trapped moisture (water) beneath the insulation. The pressure can help expel the water from the system through the WUI plug.

- Drying: After the moisture is expelled, the system might continue to blow dry air to ensure the area under insulation is completely dried. This prevents further water accumulation and reduces the risk of corrosion.

4. One-Way Valve Outside the WUI Plug

The one-way valve installed outside the WUI plug is crucial in controlling the flow direction of the expelled water or moisture.

- Function in the system:

- When the system is blown with air or nitrogen, moisture that accumulates under the insulation is pushed out through the WUI plug.

- The one-way valve ensures that once the moisture is pushed out, it cannot flow back into the system. It essentially prevents any unwanted backflow of water or contaminants into the insulated area, maintaining a clean, dry, and corrosion-free environment.

Putting it All Together: Process Flow and Benefits

Here’s how this all comes together in the system:

-

Water Detection: The corrosion rate probe (ER probe) monitors corrosion rates due to the accumulation of water under the insulation or from internal factors (e.g., corrosive media).

-

Inspection: Using a vessel inspection plug, you can check the condition of the internal structure of the vessel, deploy probes, and potentially identify if moisture buildup (WUI) is affecting the integrity of the insulation or causing corrosion.

-

Moisture Management: The WUI plug is installed at a point where moisture can accumulate under the insulation.

- To remove trapped moisture, dry air or nitrogen is blown into the vessel through the inspection plug, forcing the trapped water under the insulation to exit through the WUI plug.

- The one-way valve ensures that once the water is removed, it cannot flow back into the insulation, preventing the cycle of moisture accumulation and corrosion.

-

Corrosion Prevention: With the WUI moisture removed and the internal corrosion rates being constantly monitored, the system helps reduce the risk of damage caused by trapped water, corrosion, and the breakdown of the insulation.

Advantages of This Approach:

- Prevention of Corrosion: By constantly monitoring corrosion rates using the ER probe and eliminating moisture under the insulation, you significantly reduce the risk of corrosion-related failures.

- Non-Invasive Monitoring: The vessel inspection plug allows for easy access to the internal conditions of the vessel or pipe without the need for more invasive disassembly.

- Moisture Management: The WUI plug with a one-way valve effectively deals with trapped moisture, preventing water from accumulating and causing localized corrosion.

- Proactive Maintenance: The system allows for proactive, predictive maintenance, based on real-time corrosion data and moisture levels under insulation. This leads to fewer unscheduled shutdowns and lower maintenance costs.

Key Considerations:

- Proper Calibration of ER Probe: Ensure that the ER corrosion rate probe is calibrated and positioned at appropriate points to provide accurate and actionable data.

- Regular Inspection of WUI Plugs: Even though the one-way valve prevents backflow, regular inspections of the WUI plugs should be carried out to ensure they are functioning correctly and not clogged.

- Air or Nitrogen Supply: The system will need a reliable source of dry air or nitrogen for the blow-dry process. Make sure the supply is sufficient to handle the size of the vessel or pipeline being monitored.

This combination of corrosion monitoring, moisture management, and air-driven drying is an effective strategy to maintain the integrity of vessels and pipelines, preventing both corrosion and water-related damage.