Which valve flange fittings joints pump equipment protective cover should you choose?

Which valve flange fittings joints pump equipment protective cover should you choose?

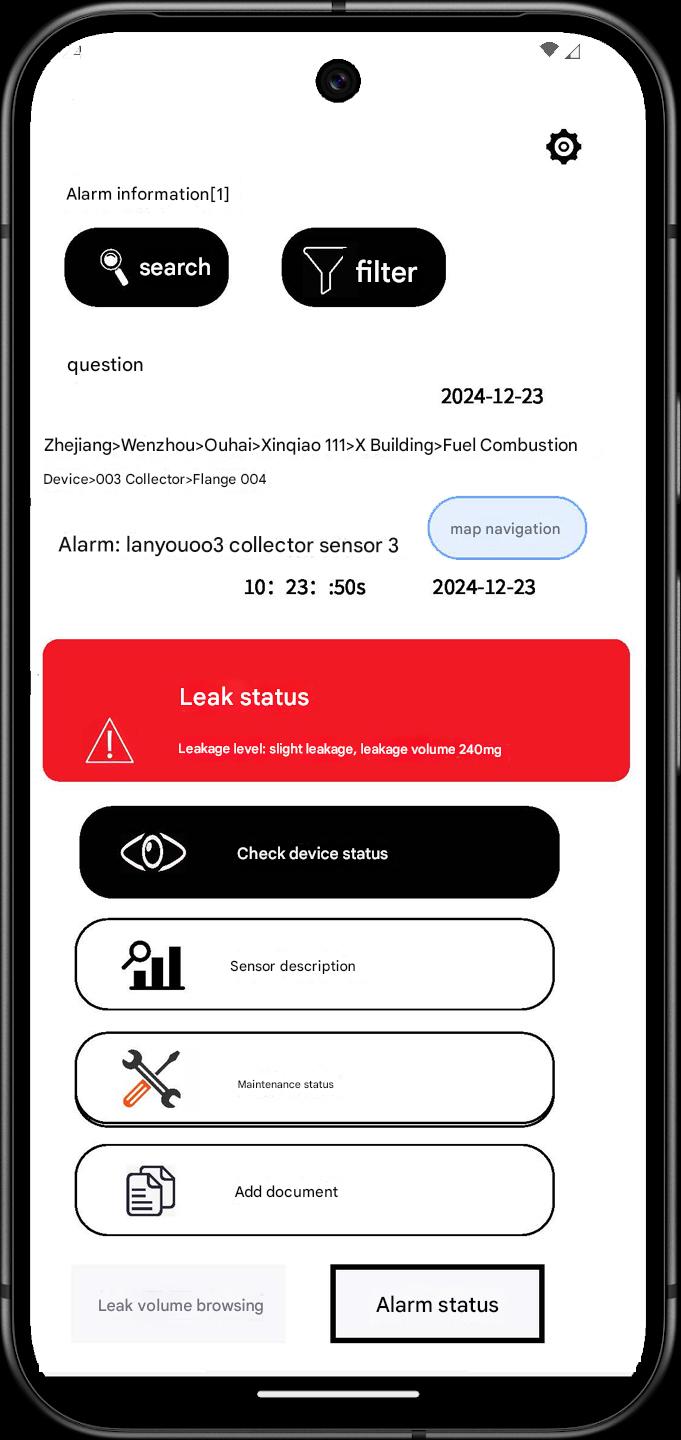

We should understand that in the enterprise production activities, there are a large number of pipelines for the transportation of liquid hazardous chemicals, hazardous chemicals, highly corrosive, joints flanges valves pumps and other gaskets will be due to thermal expansion and contraction, aging and other reasons, the formation of leaks occurring after the formation of pipeline valves, "running, bubbling, dripping, leaking".

I. Liquid

At present, the main domestic anti-splash cover, the current market common materials: PP plastic cover, PP sewing magic cover, PVC transparent sewing magic cover, PTFE sewing magic cover, metal shell splash cover, metal with splash cover

1.PP flange guards

Production needs mold to injection molding, generally for PP materials, Japan and South Korea have produced PVC transparent plastic sealing cover, in the country is mainly PP plastic flange cover.

PP plastic flange cover installation is simple, the upper and lower shells using snap-on installation of transparent, can prevent a certain amount of dripping, generally will not be added to the liquid discharge nozzle or liquid discharge valve, the size of the adaptability of the low, is still mainly used for flange splash protection, the market is mainly in the DN300 and DN 300 the following, the cover and the pipe joints with a larger gap. The aging resistance is general, the volume is larger, the transportation cost is higher. The upper and lower shell joints are easier to

The upper and lower shells are easy to be deformed due to injection molding, and may not fit well.

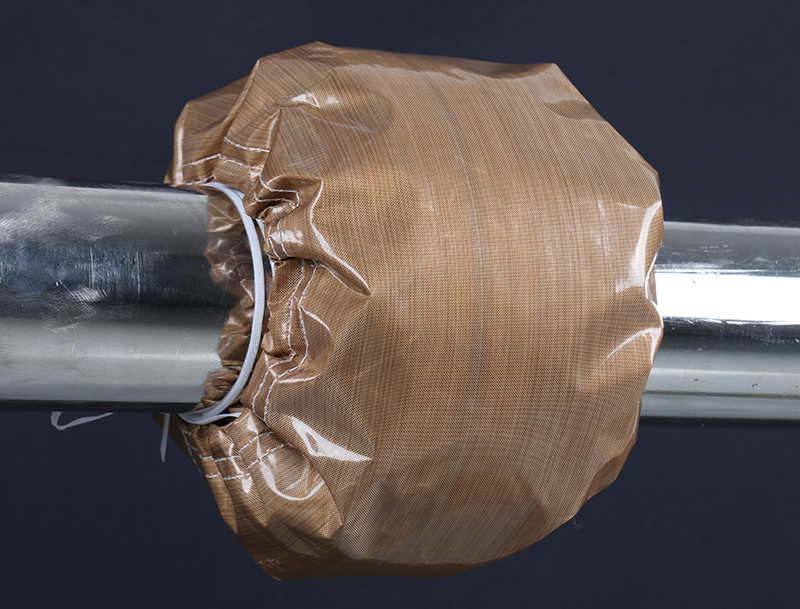

2 PP Sewing Velcro spray shields

2.1 PP Sewing Velcro spray shields

The polypropylene cover adopts sewing technology, its advantages are: the lower end and the bottom surface are made of polypropylene non-woven fabric or composite leather, the upper end is made of soft material and enclosed to form the open end; the side wall is equipped with an adjusting piece for adjusting the diameter of the open end. The bottom surface of the flange guard and the lower end of the side wall are made of polypropylene non-woven fabric or composite leather, which can effectively prevent splash damage to employees and equipment. It is breathable, environmentally friendly, wear-resistant, oil-proof, waterproof, effectively reduces the temperature inside the pipe, and greatly reduces transportation costs, and by adjusting the size of the diameter of the open end it can be made suitable for various diameters of the pipe, reducing production costs. Because it is sewing technology can be customized according to the size of the pipe or equipment any

At present, it is mainly used indoors for pipeline splash protection, general aging resistance, opaque, generally do not add the drain nozzle or drain valve, the leakage liquid is easy to drip from the sewing place in the workshop, easy for people to fall over, the drip liquid contamination of the workshop or soil.

2.2 PVC Sewing Velcro spray shields

The flange spray shield is mainly made of PVC transparent film and customized polypropylene cloth on both ends. Transparent, can effectively prevent splash damage to employees and equipment. Better aging resistance, generally used for outdoor room temperature. Generally do not add drain nozzle or drain valve, the leakage liquid is easy to drip from the sewing place in the workshop, outdoor construction site. It is easy for people to fall down, and the dripping liquid will pollute the workshop, construction site or soil.

2.3 PTFE/Fluorocarbon Coated Fabric + FEP Clear Sewn Velcro spray shields

The flange spray shields is mainly made of FEP transparent film and customized PTFE cloth or Teflon coated cloth on both ends. Transparent, can effectively prevent splash damage to employees and equipment. Good aging resistance, generally used for indoor and outdoor high temperature Higher price, generally do not add the drain nozzle or drain valve, leakage liquid is easy to drip from the sewing place in the workshop, outdoor construction site. It is easy for people to fall down, and the dripping liquid pollutes the workshop, construction site or soil.

T

2.4 Teflon Coated Fabric Sewing Velcro spray shields

Mainly made of Teflon coated fabric with high UV resistance, high temperature resistance, high corrosion resistance and suitable price.

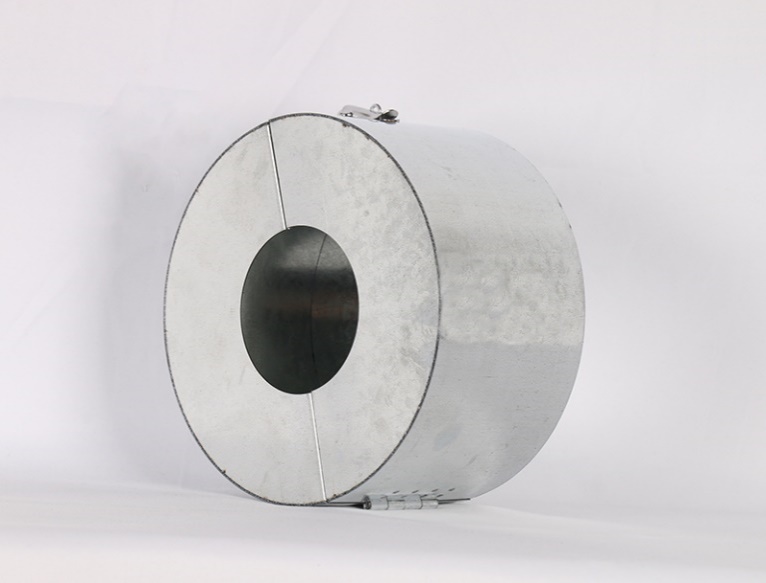

3. Metal splash guards

3.1 Shell type

Generally made of metal (galvanized, stainless steel), using laser cutting, rolling round, laser welding, spray gun spot welding technology, can be effective splash protection for high temperature liquid splash, can be with a deflector. Anti-drip. Higher price.

3.2 Belt type

Generally made of metal stainless steel, with a steel belt with a rounded pressure gun welding buckle goods throat hoop. The price is cheaper than the hood type, can be with a deflector tube

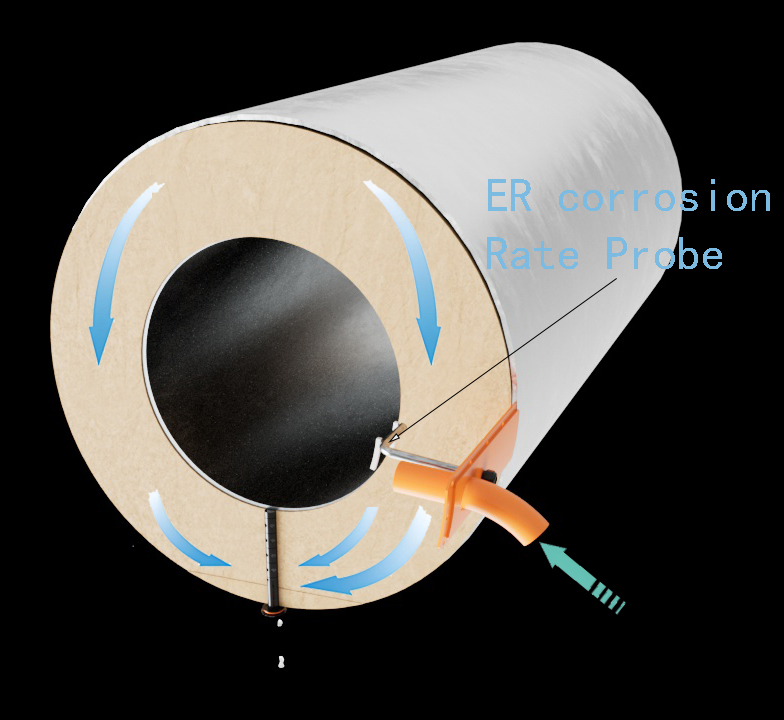

4.Seamless welding flexible flange and vlave guards

Seamless welding technology, is a Wenzhou leakage corrosion of the first proposed, the use of molding technology, self-adhesive alternative to sewing Velcro, fit, anti-liquid dripping in the workshop so that the staff slipped and fell, pollution of the environment More mainly to prevent flammable and explosive liquids dripping on the floor to prevent a fire.

4.1.PVC transparent cover with deflector tube

Adopting molded welding technology and anti-static flame retardant material, with a deflector nozzle, transparent, anti-liquid spattering and dripping, large capacity. Due to the seamless welding technology, without any sewing technology, the weld is solid, fully transparent, the leakage is visible The leakage liquid inside the cover will not drip in the workshop, and will not let the staff slip and contaminate the workshop and soil. Can be customized to customer's various shapes of equipment at will.

4.2 PP welding flange and vlave with deflector cover

Adopting molded welding technology, the material is made of breathable PP material, suitable for corrosion of easily volatile VOCs liquid, internal leakage liquid will not drip in the workshop, will not let the staff slip and workshop and soil pollution. Can be customized to various shapes of customer's equipment4.3 PVDF

PVDF seamless drainage tube

Adopting PVDF coated cloth, good aging resistance, better low and high temperature resistance. Cheap price, can replace Viton coated fabric sewing velcro cover.

4.4 Glass fiber cloth

Adopts zipper coating technology, generally used for high temperature liquids up to 450 degrees. Drip-proof, leak-proof and mainly fire-proof. Can also be used with gas

二.Gas (continued...)

Foreign countries have adopted hard shell double tube technology, but the cost is high. Installation trouble. Currently leakage corrosion using flexible zipper technology and special sealing technology (domestic and foreign rarely use this technology), the main materials are PVC, PVDF, TPU, EVA and fiberglass. Suitable for low pressure