PVC/PVDF Splash and Drip Resistant Transparent piping leak containment Cover with Drainage Control

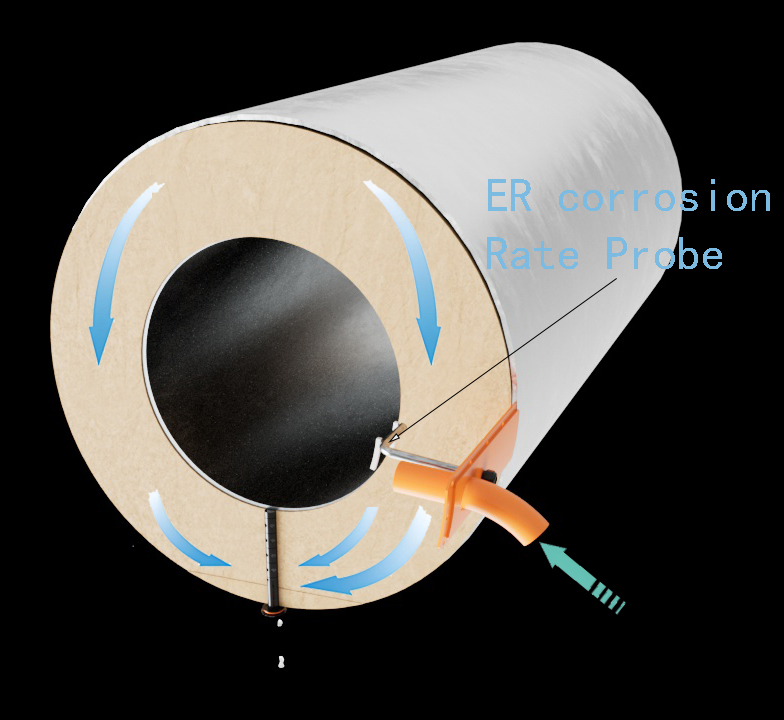

Made from PVC (Polyvinyl Chloride) or PVDF (Polyvinylidene Fluoride). Let's break down the features and benefits based on your description: Material: PVC or PVDF - Both materials are popular in industrial applications for their chemical stability and mechanical properties. PVDF, in particular, offers excellent resistance to creep and fatigue, as well as to acids, solvents, and heat, making it suitable for harsh environments. Large Capacity and Transparency - The leak cover appears to be large enough to handle substantial leaks, and being transparent, it allows for visual inspection of the pipe and the contained leak. This is crucial for monitoring the leak's status without removing the cover. Leak Containment Features: Anti-Splash and Anti-Drip - These features help manage and contain the leak effectively, reducing the risk of splashes and drips, which are common in pressurized systems. Flame Retardant and Fire Resistant - These safety features are critical in environments where there's a risk of fire, providing an additional layer of security against potential fire hazards caused by leaking flammable liquids or gases. Anti-Static - This property is important in preventing static discharges, which can be a significant hazard in industries dealing with flammable substances. Diverter Valve - This inclusion suggests that the cover can redirect the flow of leaked fluids, possibly into a containment system or away from sensitive areas. This is particularly useful during ongoing leak management without stopping system operations. Zero Contamination and Corrosion Resistance: Zero Contamination of Floors - The design prevents any leaked fluids from reaching the floor, thereby maintaining cleanliness and reducing slip hazards. Corrosion Resistance - Both PVC and PVDF are inherently corrosion-resistant, but the cover's ability to add VCI (Volatile Corrosion Inhibitors) anti-corrosive kits and desiccants enhances this. These additions help protect the metal parts of the pipeline within the cover by neutralizing corrosive agents and controlling humidity. Airtight Design - The mention of an airtight design indicates that the cover provides a sealed environment. This feature is essential for effective use of desiccants and VCI kits, as it prevents external air and moisture from entering and promotes an effective micro-environment for corrosion protection. This type of leak containment system is invaluable in industrial settings where pipeline integrity and environmental safety are critical. It not only helps in managing unexpected leaks effectively but also ensures compliance with safety and environmental regulations by preventing ground or water contamination.