Is there a better priced, safer and more environmentally friendly technology than LDAR?

Is there a better priced, safer and more environmentally friendly technology than LDAR? VOCs (Volatile Organic Compounds) react with nitrogen oxides and form ozone when exposed to sunlight and heat, which contributes to poor air quality and is a major component of summer smog.

In the petrochemical industry, leaks from piping and process line equipment (e.g., valves, flanges, pump seals, flanges, pressure relief valves, etc.) produce large amounts of VOCs that are emitted into the atmosphere, and the leaks are not easily detected. This leads to a large area of long-time heavy haze for a long time, according to the U.S. EPA survey, equipment leakage caused by VOCs emissions

According to the U.S. EPA survey, the amount of VOCs emissions caused by equipment leakage far exceeds that of container storage, sewage stations, transfer operations, ventilation processes, etc., and leakage emissions mainly come from valves and interfaces, accounting for more than 90% of the total leakage emissions.

Although the traditional LDAR can locate and monitor the leakage point, the leakage point has already polluted the environment after leakage, and the cost is relatively large.

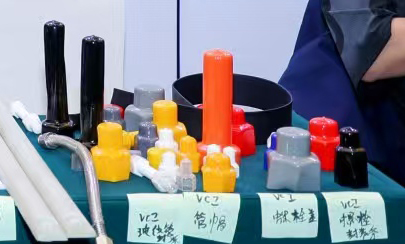

There is no sealing point (easy to leak points such as valves, flanges, connections, pumps, pipe openings, etc.), to carry out accurate sealing point positioning protection, so that there are leakage potential points more intuitive, safe, environmentally friendly, systematized it?

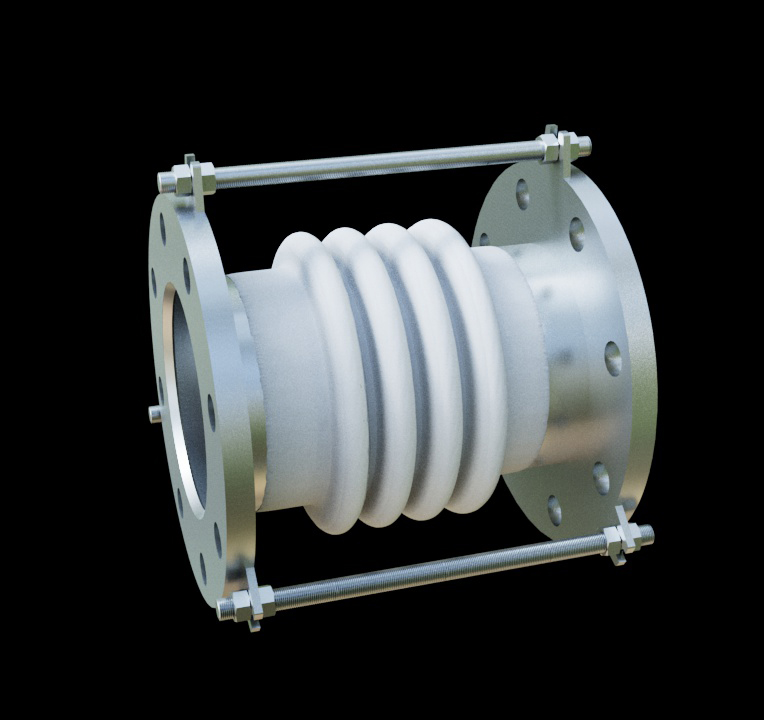

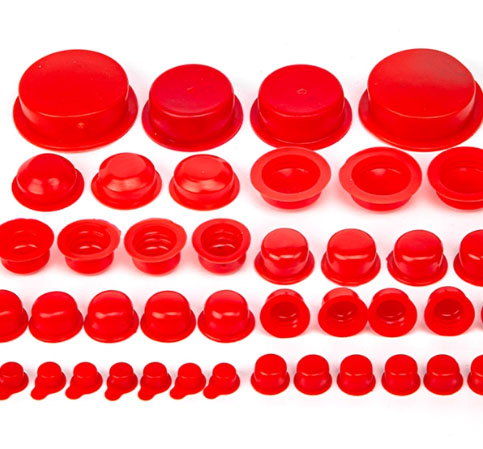

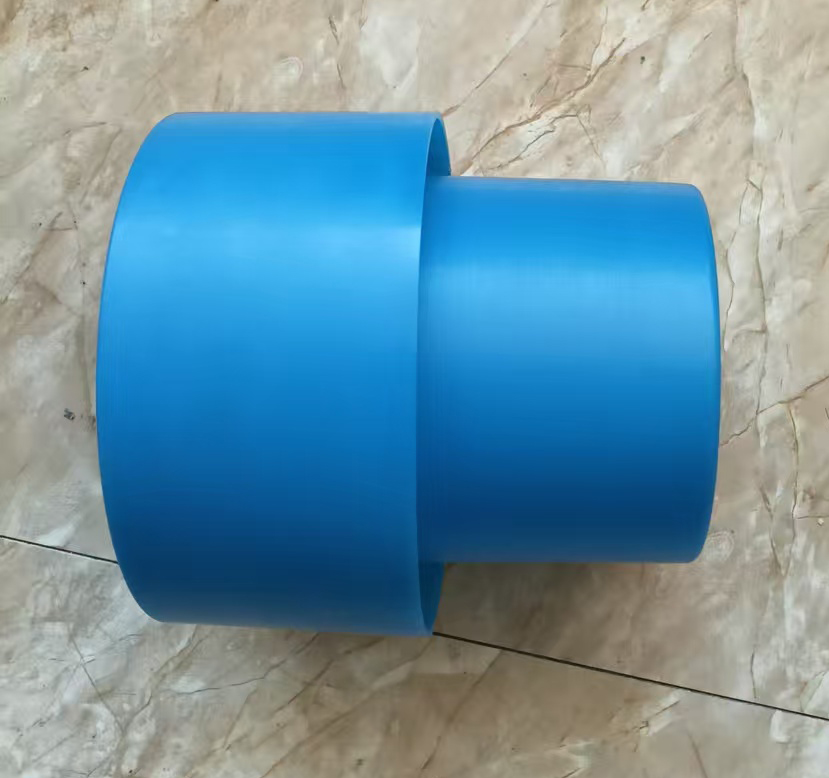

The answer is yes, through the transparent fire prevention and anti-static material on the sealing point (prone to leakage points such as valves, flanges, connections pumps, pipe openings, etc.) for secondary protection, such as double tubes or hoods to use the zipper and adhesive seal leakage blocking type module technology and diversion of the collection of monitoring and processing technology, the sealing point of the secondary protection, so as to achieve zero pollution of the environment, safer and less costly.

Transparent double tube or hood is not just a protection visualization technology, it is a management model. Through the process equipment and pipeline sealing points for periodic testing (the hood can accommodate 1 to 15 days of leakage) and real-time maintenance of the leakage points found, to achieve the overall online management of the operation of the phenomenon of unorganized emissions of VOCs, protection and monitoring of the purpose, can be found in advance of the site of the production of potential safety hazards, to improve the safety and reliability of production; can be effective in reducing the emission of VOCs enterprises, thereby improving the local air quality; can also effectively reduce VOCs emissions. It can effectively reduce VOCs emissions from enterprises and thus improve local air quality; it can reduce the risk of pollution exposure for on-site workers; it can effectively reduce material losses in enterprises and obtain more production benefits; it can detect equipment leaks in advance and repair them earlier, thus reducing maintenance costs.