How to protect to flange raise face during ,,storeage ,transportation,welding, sandblasting and coating?

The flange raised face is an important component used to connect two pipes or equipment. Protecting the integrity of the flange raised faces

is critical to ensuring the proper operation of the pipeline or equipment. In this document, several common measures for protecting flange sealing faces are discussed to ensure their long-term reliability and durability.

I. Proper Packaging ,storage and Transportation

Proper packaging is the first line of defense in protecting flange sealing faces during transportation and storage. Commonly used packages, such as plastic caps, plastic strips, wooden boards or corrugated boards, can prevent sharp or heavy objects from colliding with each other during transportation, so as to avoid scratches or bruises on the sealing faces.

Plastic lids and strips can easily fall off, and cardboard and wooden boards should be cut and tied.

In the storage process, the plastic cover, plastic strips or wooden boards, corrugated cardboard can not prevent rust and oxidation.

And we are used 1.95mm high strength cardboard discs, for the flange sealing surface exposed to harsh environments, to prevent the surface of the flange sealing surface from corrosion, deposits and pollutants, anti-collision, anti-rust and anti-oxidation, in the process of storage and transportation to effectively avoid the flange sealing surface scratches, bruises, and the flange sealing surface rust, installation and disassembly of a post a tear can be!

2. Welding flanges, especially flat welding flanges to prevent oxidation

1. Surface coating: A layer of antioxidant coating, such as graphite, silicone oil, etc., can be applied on the sealing surface of the flange. These coatings can effectively prevent oxidation reaction, reduce surface decarburization and lower the occurrence of deformation. 2.

2. Use of protective agent: Before heat treatment, the sealing surface of the flange can be moistened or sprayed with protective agent to form a protective film. This can effectively isolate the entry of oxygen and prevent surface oxidation and decarburization.

3. Use cardboard flange ring flange stickers to stick on the sealing surface of the flange to isolate the oxygen from entering the sealing surface and prevent surface oxidation and decarburization from occurring.

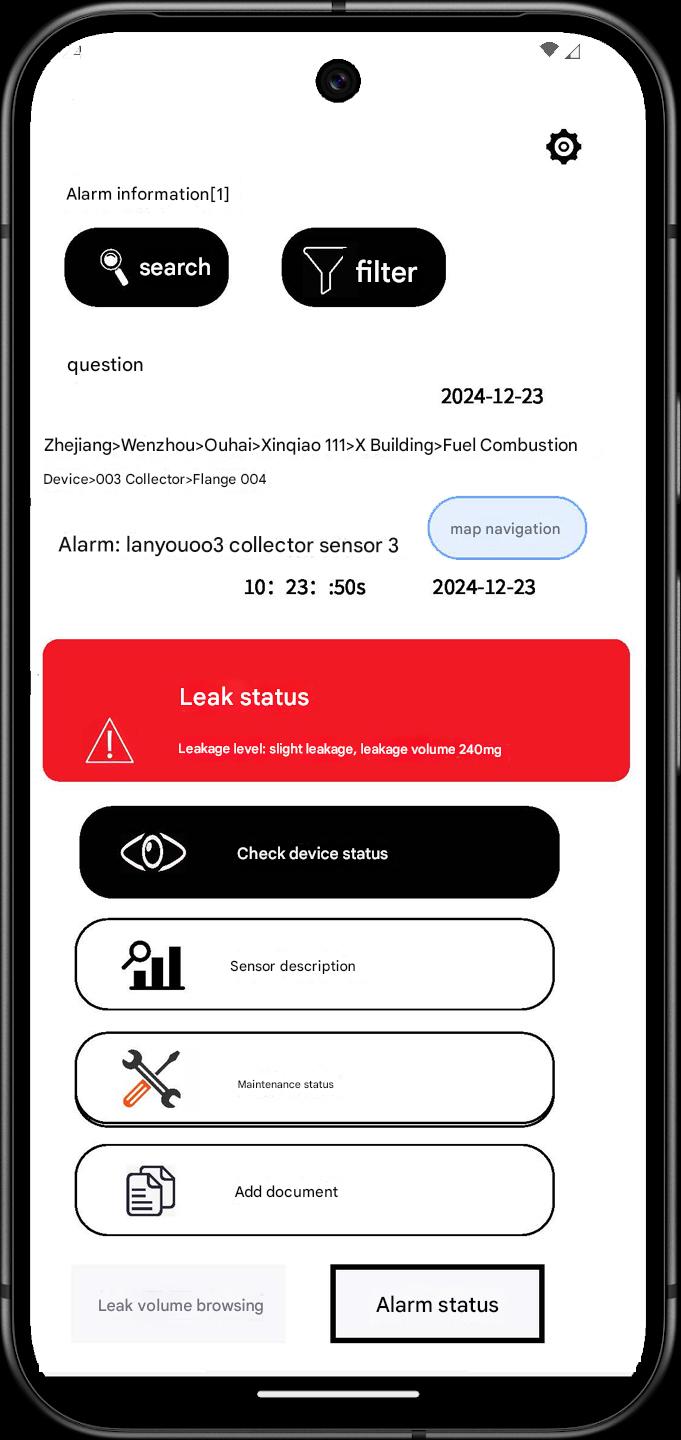

3.Sandblasting coating sealing surface protection

1. Iron plate, the current domestic mainstream is to cover the sealing surface with an iron plate, and then fixed with wire, wire fixed place sandblasting spray can not, of course, can be rotated, the efficiency is low, and the iron plate and the sealing surface is not necessarily 100% fit sealing, small particles of sand is easy to enter the sealing surface, so that sand particles are easy to damage the sealing surface of flanges

2. Cardboard paste, using high-strength 1.95mm yellow waterproof cardboard, self-adhesive in the flange sealing surface, sealing and isolation of the flange sealing surface sand particles and paint air can not enter the sealing surface, can effectively protect the flange sealing surface.

Conclusion

Measures to protect the sealing surface of the flange is to ensure the normal operation of the pipeline or equipment is an important link.

The pressboard flange raised face is an important part to ensure the normal operation of the pipeline or equipment. Through appropriate packaging, transportation, storage, welding, sandblasting, painting and other flanges a series of assembly process sealing surface protection analysis, high-strength waterproof cardboard sticker is currently a better choice.