how to detection and protection gas and liquild leak

As one of the most important forms of environmental pollution, gas pollution has the outstanding characteristics of rapid diffusion and wide range of influence. It is more ambiguous for some colorless, odorless and toxic gases.

Increase the difficulty of people's prevention. Therefore, once a highly toxic gas leaks, it may cause a big bang in a short time.

The number of casualties; and in a short period of time, it is difficult to completely remove residual hazardous gases. Dangerous gas means easy

A toxic, explosive gas that is flammable. Long-term living in a slightly dangerous atmosphere can cause people to remember

Relief, vomiting, dizziness, convulsions, irritability, and other functional diseases; when humans are exposed to high concentrations of dangerous gas

When it is in the body, it may immediately destroy the human body's breathing and nervous system, and even cause death. Dangerous in industrial production

The leakage of the body not only causes environmental pollution, but also poses a serious threat to the lives and property of the staff.

Traditional detection

For trace gas detection methods, according to the working principle, it can be divided into two categories: spectral and non-spectral analysis methods:

Spectral analysis method

Spectral analysis methods are mainly based on different gas molecules with different 近 in their near-infrared and mid-infrared bands.

The characteristic absorption and scattering spectra are used to discriminate the concentration of the gas, and the line is strong at the characteristic line according to different gas molecules.

The gas concentration can be determined for qualitative and quantitative detection purposes. Spectral detection analysis is mainly divided into: Fourier

Transformed infrared spectroscopy (FT1R) [1G], differential absorption spectroscopy (DOAS) [11], tunable laser absorption pupil

Spectral Method (TDLAS) [Smart and Laser Photoacoustic Spectroscopy (PAS) ["], etc.

2. Non-spectral analysis methods mainly include ultrasonic technology, semiconductor gas sensing method, thermal catalytic method, gas phase enthalpy

Chromatographic method and optical drying method, etc. These methods generally have a commonality, that is, the sample needs to be sampled.

As a result, it cannot be applied to real-time online measurement, and it is impossible to track the change of gas concentration in real time;

High environmental requirements, susceptible to high temperature, high pressure, vibration and dust interference; for complex or evil

Inferior site environmental conditions have certain limitations; only for single point measurement and environmental conditions are relatively stable;

Non-uniform distribution of gas concentration, measurement results are poor; at the same time, some of them can detect gas

The type is limited, and there are certain limitations for the measurement of various gas concentrations and the maintenance cost of the equipment is high.

But the traditional method has high cost and high cost, and there is no secondary leakage seal. Fujin Guoxin Hardware

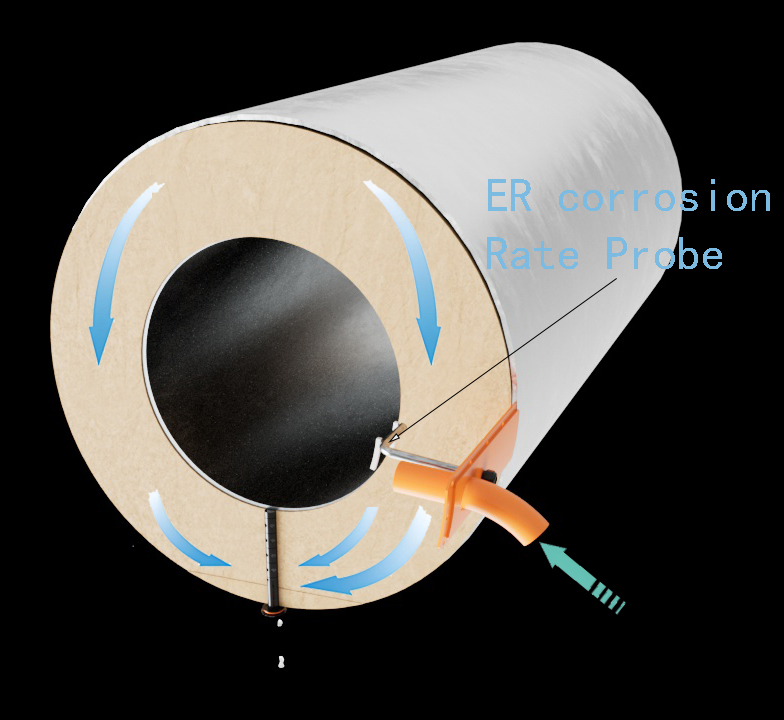

The use of flexible materials, high temperature resistance, aging resistance, weather resistance and other composite materials, self-adhesive packaging, plus sealing gaskets, and clamps, etc., to make the internal pressure of the sealed pipe or equipment.

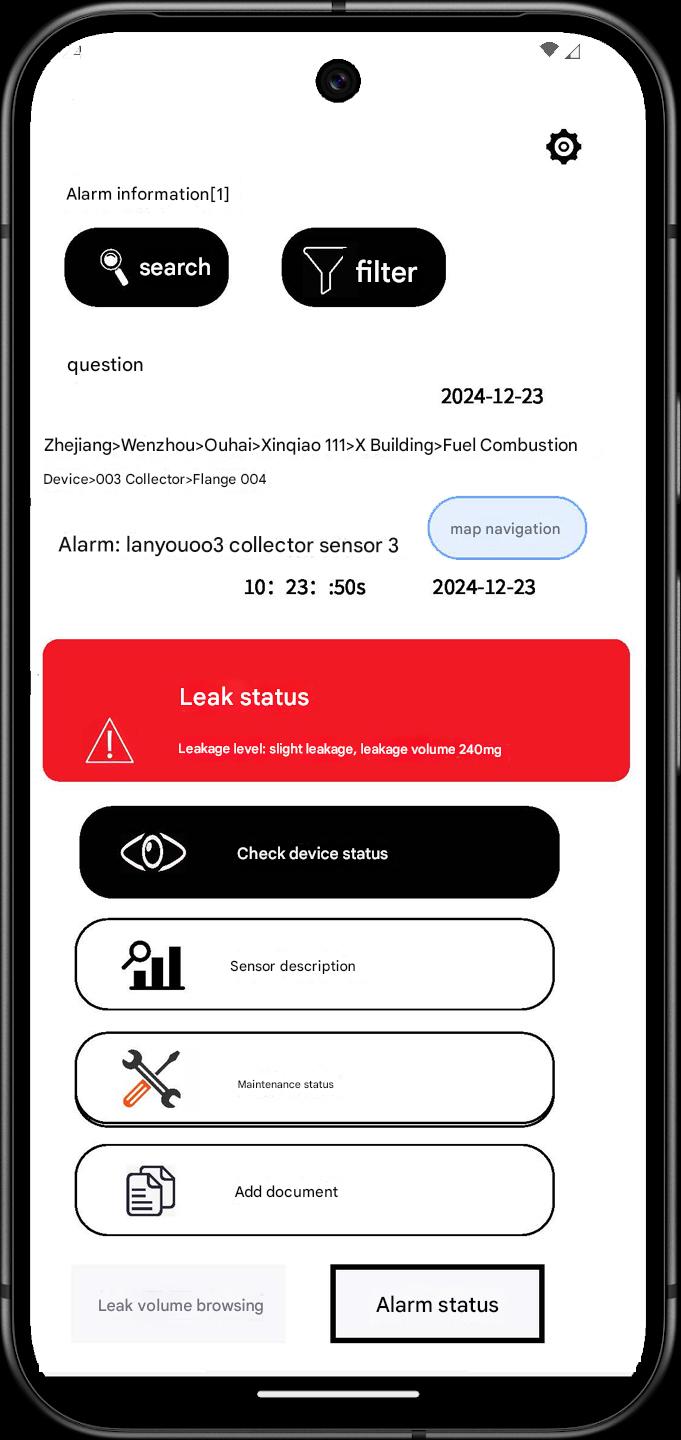

It can effectively prevent leakage of gas and liquid, leak to the atmosphere, and then pass the pressure sensor. Once the packaging material is broken, or the gas and liquid leak, the pressure sensor will detect it immediately and automatically notify the maintenance personnel through APP or other means. Then automatically close

The valve is controlled, the valve of the diversion tube is opened, and the gas-liquid dangerous body leaked out is discharged through the diversion tube for secondary recycling, which is safe and environmentally friendly.