How to choose VCI flange protection materical?

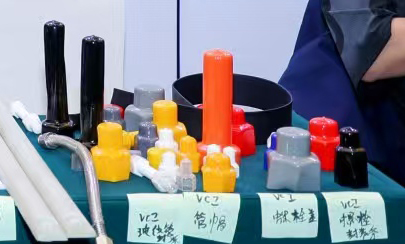

It is well known that solid or liquid VCI active substances or mixtures of VCI active substances are coated or mixed into packaging materials such as plastic films, paper, cardboard, foam, composites, etc.

It is known that solid or liquid VCI active substances or mixtures of VCI active substances are coated or blended into packaging materials such as plastic films, paper, cardboard, foam, composite materials, etc. In this case, VCI-impregnated paper and cardboard can be quickly and initially protected against corrosion using methods such as impregnation, spraying, coating or blending with the aid of extrusion and the like, but not for long periods of time. Plastic films and other polymer carriers release their VCI effective substances much more slowly.

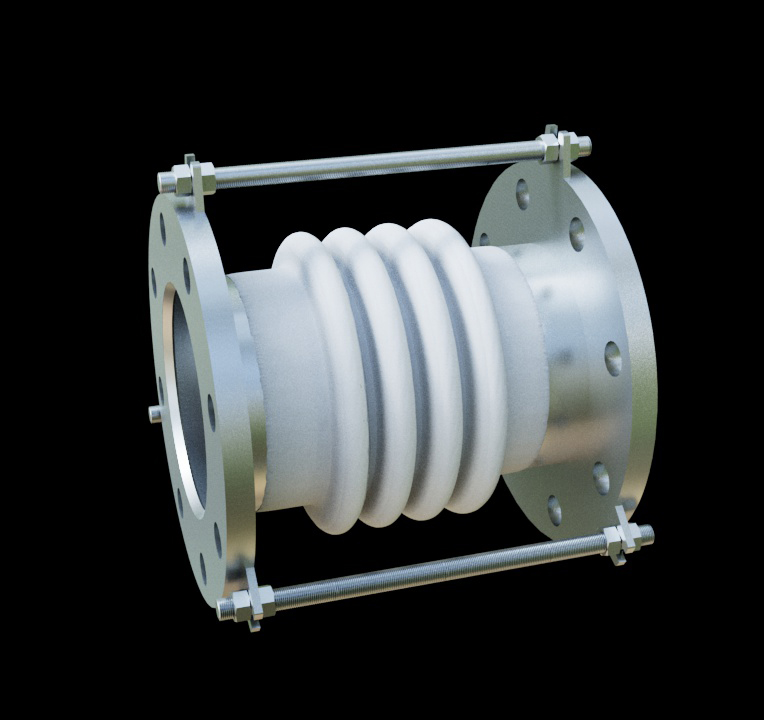

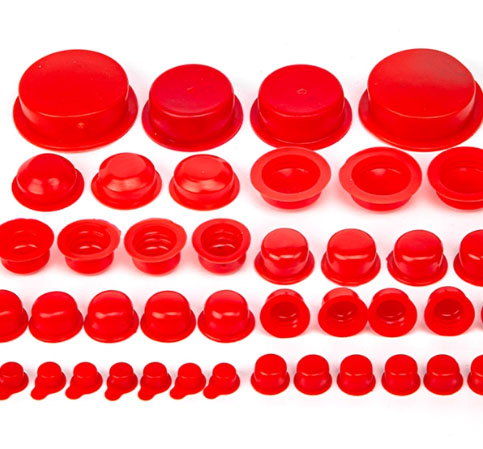

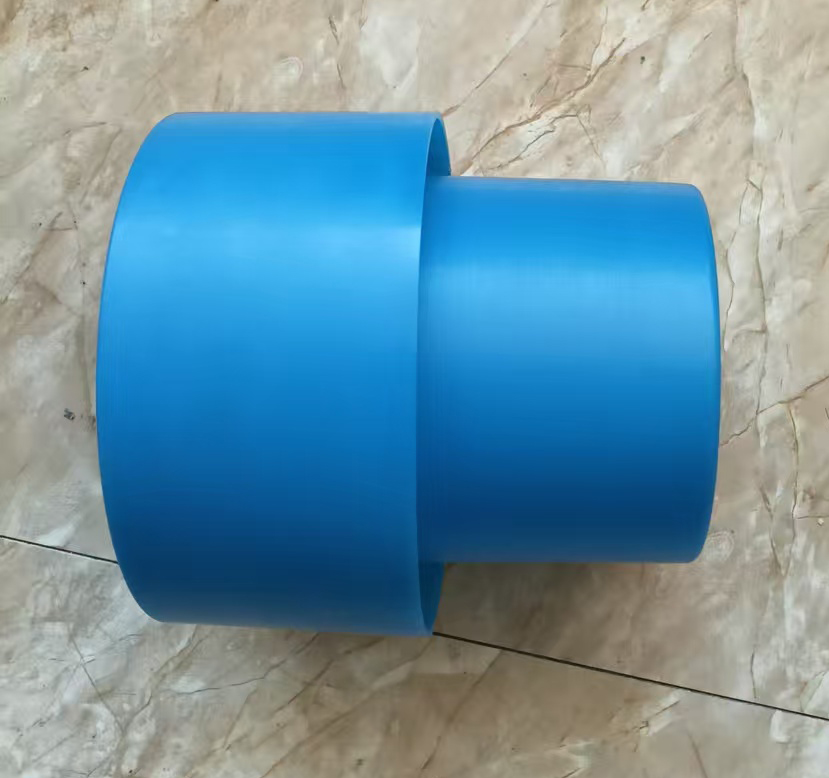

effective substances much more slowly. Therefore, they do not provide corrosion protection as fast as paper, but they are more effective for flange patches, and ordinary VCI PE 200um (a relatively thick VCI thickness) is still too thin for flange patches. Pearl cotton and other foams have a strong anti-collision ability. But too many bubbles, VCI release too fast, so the LCH using a unique barrier material and glue VCI formula, in the thickness and slow release, no residual glue to do their own ratios and optimization.