Flange Leak Guard Specification

Overview

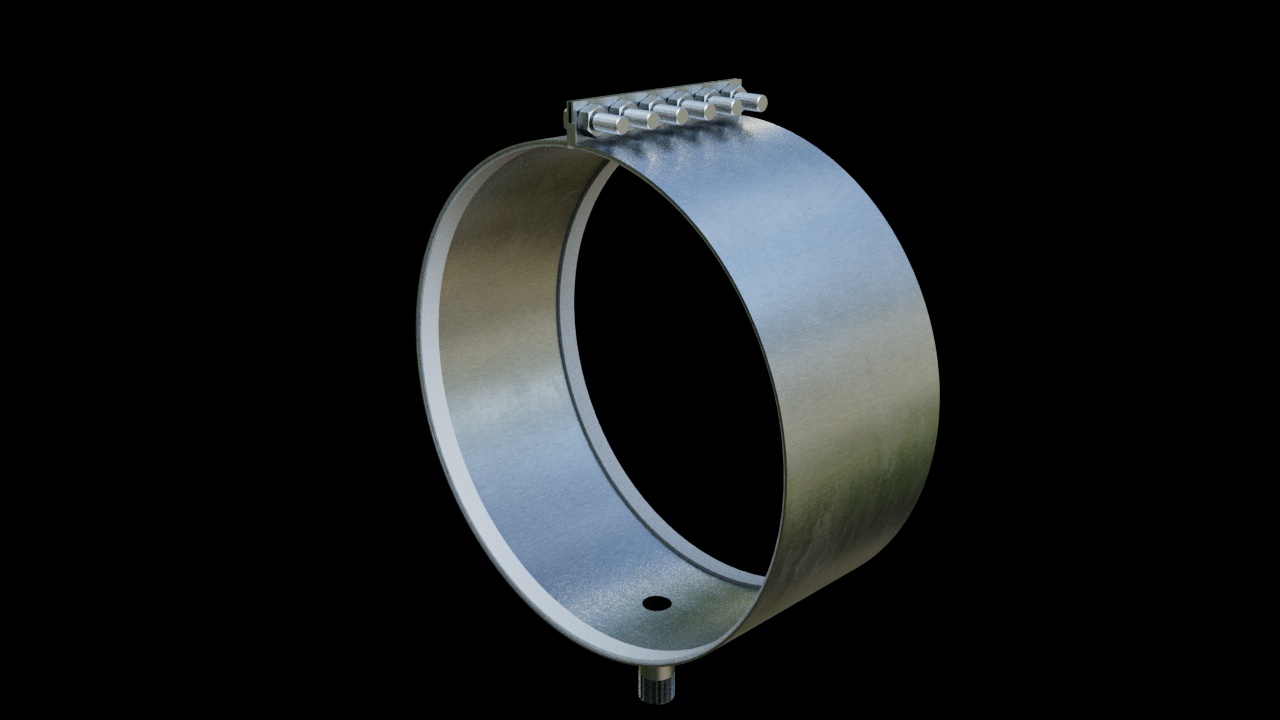

This specification outlines the design and material requirements for a flange leak guard constructed from AISI 316L stainless steel, intended for use with expanded 100% PTFE gasket tape. This guard is specifically designed to provide reliable sealing in applications involving chemicals, liquid natural gas (LNG), and cryogenic temperatures.

Key Features

- Material: 100% AISI 316L stainless steel, known for its excellent corrosion resistance and suitability for harsh environments.

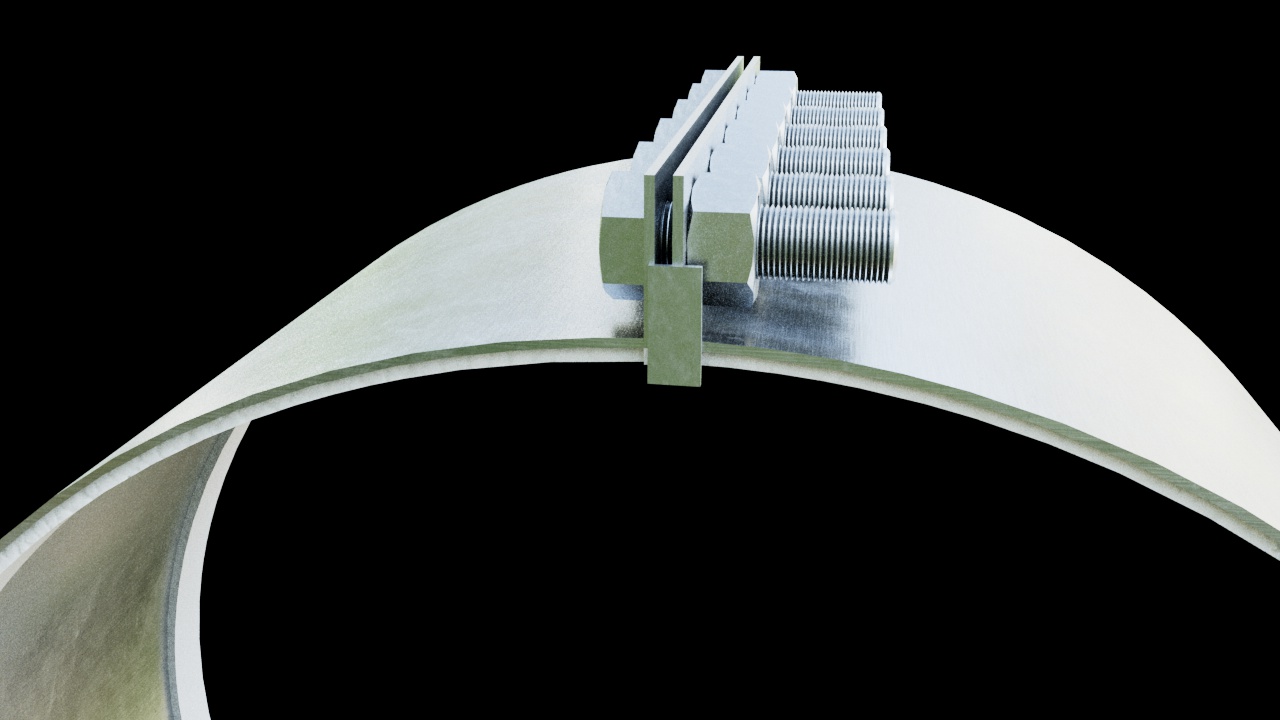

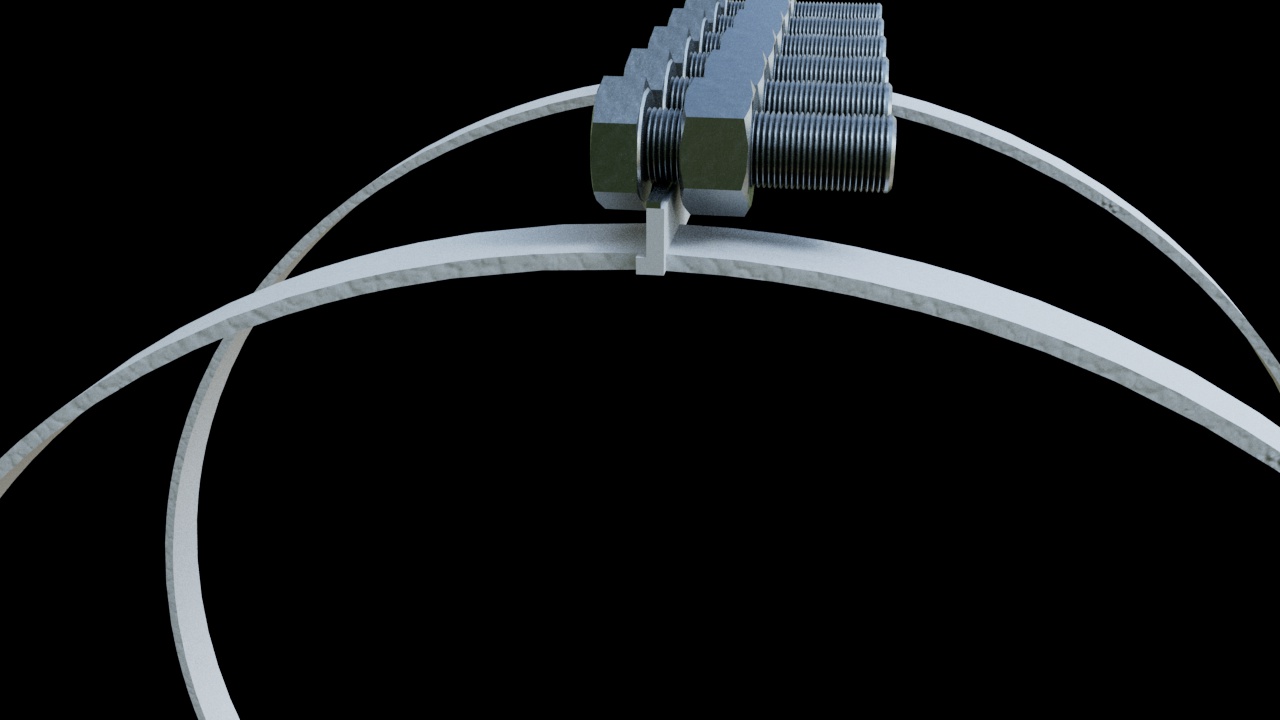

- Gasket: Expanded PTFE gasket tape for enhanced sealing performance, particularly effective with a wide range of chemicals and at cryogenic temperatures.

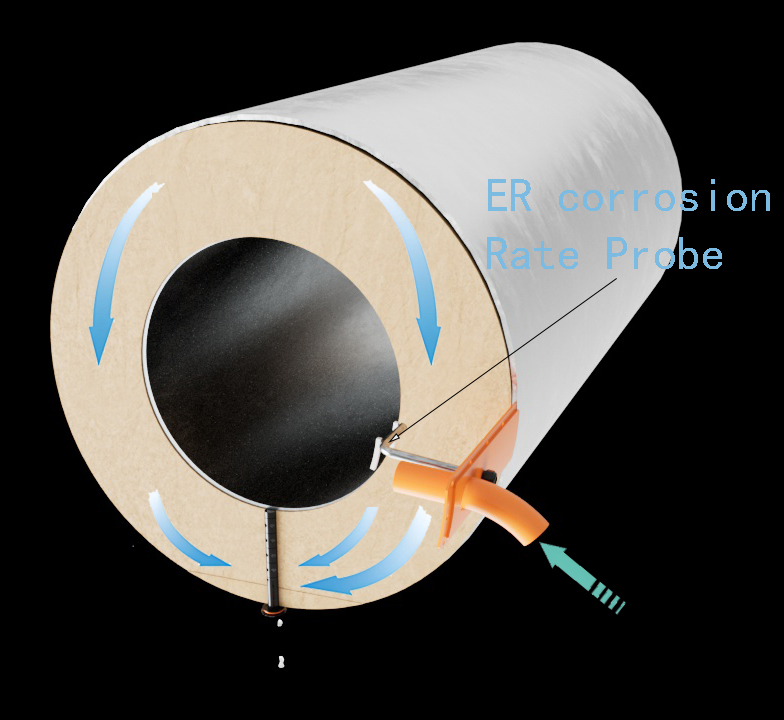

- Drain Pipe: An integrated drain pipe allows for the safe conveyance of any leaks, directing fluids away from sensitive areas to minimize risk and facilitate safety.

Applications

- Chemicals: Suitable for handling a variety of corrosive and non-corrosive chemicals, ensuring integrity in chemical processing and transport.

- Liquid Natural Gas (LNG): Designed to operate effectively in the transportation and storage of LNG, which requires robust sealing solutions due to its cryogenic nature.

- Cryogenic Temperatures: The design accommodates temperatures ranging from -196 °C to +270 °C, making it versatile for various industrial applications.

Technical Specifications

- Maximum Temperature: +270 °C

- Minimum Temperature: -196 °C

- Maximum Pressure: 50 bar

Design Considerations

- Flange Design: The flange should have appropriate dimensions to fit standard pipeline configurations, ensuring compatibility with existing systems.

- Gasket Compression: The expanded PTFE gasket tape should be installed with proper compression to optimize sealing performance while allowing for thermal expansion and contraction.

- Drain Pipe Installation: The drain pipe must be securely attached and routed to an appropriate disposal area to handle any potential leaks, preventing environmental hazards.

- Surface Finish: Ensure that all stainless steel surfaces are adequately finished to minimize surface roughness, which can affect the sealing capability and overall performance.

- Inspection and Maintenance: Regular inspection and maintenance schedules should be established to ensure the integrity of the flange guard and the effectiveness of the gasket seal.

Safety Considerations

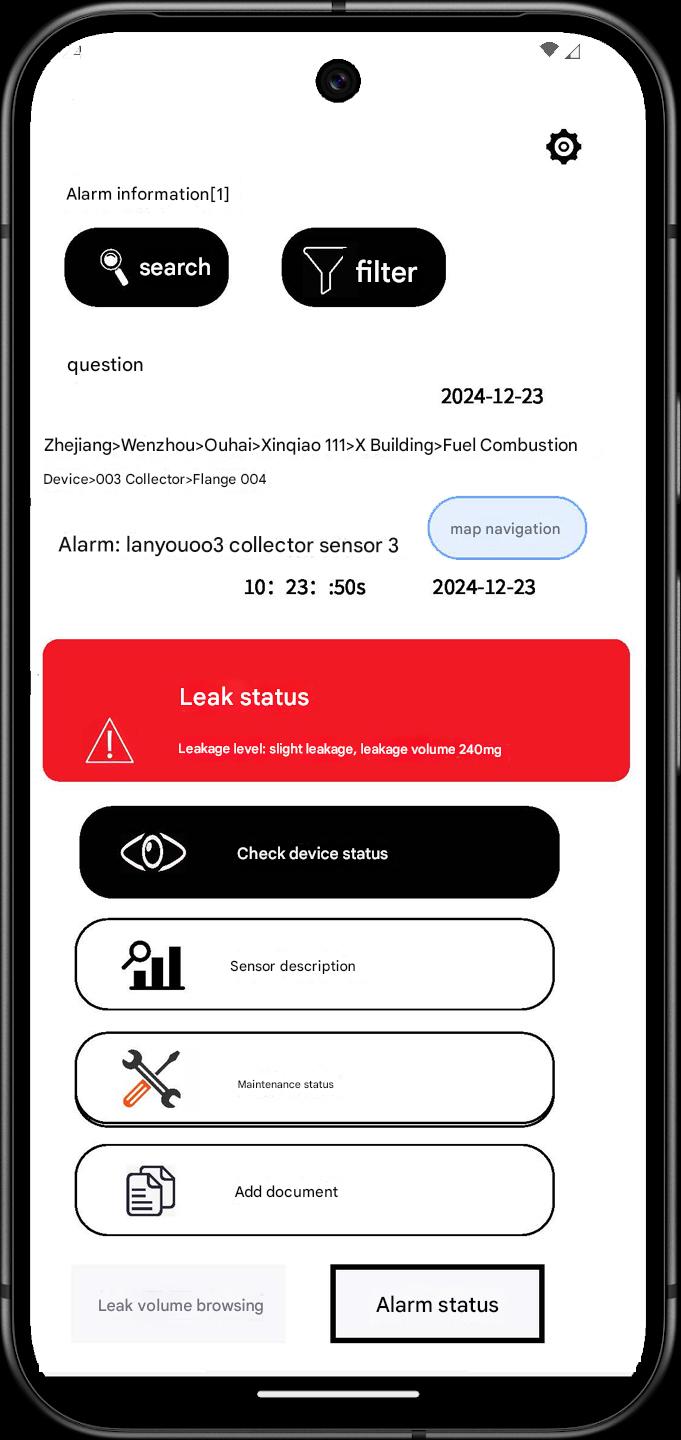

- Leak Detection: Implement leak detection systems in conjunction with the flange leak guard to monitor for potential failures.

- Personal Protective Equipment (PPE): Ensure that personnel involved in the installation and maintenance of the flange leak guard use appropriate PPE to mitigate risks associated with exposure to hazardous materials.

- Training: Staff should be trained on the handling of chemicals and LNG, as well as emergency response protocols in case of a leak.

Conclusion

The AISI 316L stainless steel flange leak guard with expanded PTFE gasket tape is engineered to meet the rigorous demands of industries dealing with chemicals, LNG, and cryogenic applications. Its robust design and safety features, including a drain pipe for leak management, make it an essential component for maintaining operational integrity and safety in these critical environments. Regular maintenance and adherence to safety protocols are crucial for ensuring long-term performance and reliability.